Design Exchange Partnerships bring design researchers together with non-academic organisations, such as businesses, NGOs or local councils, in strategic partnerships capable of addressing green transition challenges. Power of Waves is a Design Exchange Partnership project led by Ravensbourne University, in collaboration with Wood Bros Furniture, Harris Tweed Hebrides and Fishy Filaments .

This project explores how waste materials can be used to make new things. They worked with Fishy Filaments in Cornwall, Harris Tweed Hebrides in Scotland and furniture maker Wood Bros in Hertfordshire to understand the challenges of turning different waste materials, such as fishing nets and wool, into new furniture. Their first prototype, a chair, also acts as a story telling platform from which to create new narratives and imagine what a sustainable future might look like. Our Community Manager Andrea Conde Pereira spoke with Dr Shaun Borstrock and Mark Bloomfield to learn more.

ACP

Could you introduce yourselves?

SB

I'm the principal investigator on the project and the Head of Knowledge Exchange and Research at Ravensbourne University.

MB

I'm the Research Associate on the project, based at the University of Hertfordshire. Over time I have become passionate about the planet and natural resources and started to understand some of the damage that we're doing and how we can alleviate it, as well as the need to show examples so that we can take others with us on this journey.

ACP

Could you introduce the commercial organisations and communities you’ve worked with on this project?

MB

We had three commercial partners spread across the country who are also quite diverse in terms of what they do; Wood Brothers who are a traditional furniture store in Ware, Hertfordshire, Harris Tweed Hebrides, a producer of wool cloth, are up on the Outer Hebrides and we worked with Fishy Filaments who recycle end-of-life fishing nets into filaments for 3D-printing based in Cornwall.

SB

We were introduced to Harris Tweed Hebrides through another colleague who runs a fashion company and thought we'd get on. We have now been working with them for the past ten years on student projects with the University. Wood Brothers initially approached us because they wanted to work with the University on conservation, recycling and production. We initially began looking at prototypes and then when this funding opportunity came up, we decided to apply together.

MB

I was aware of Ian at Fishy Filaments because I have a great deal of expertise and experience in the 3D printing space. Ian is doing great work with communities of fishermen, and I felt that there was an interesting crossover between that and the work of the other two partners.

With partnerships like this we can tie together different companies and find that we have common issues that we're trying to solve. I think that is really important particularly when beginning to think about green transition because it's not just about reusing waste, it's multifaceted and there are lots of different aspects that really need to be almost completely rewritten.

SB

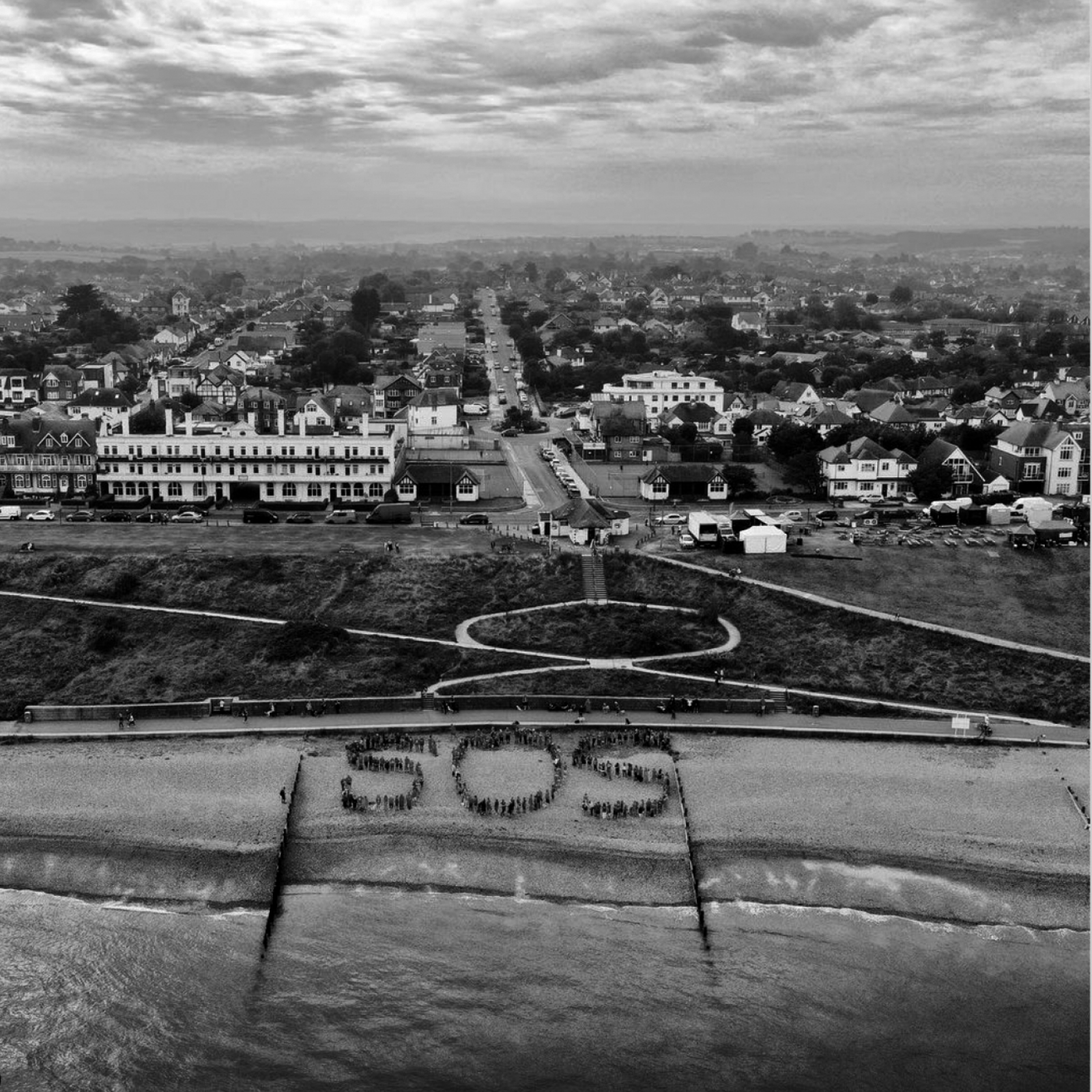

Our project has involved vast quantities of textiles, woven by different communities. The partnership gave us the opportunity to bring those communities together and make connections which wouldn’t otherwise happen. For example, we brought together communities from the Outer Hebrides – the Isle of Harris and the Isle of Lewis – in different environments varying from weaving mills to people’s garden sheds.

ACP

How can furniture design be a driver of change?

MB

There used to be a kid's TV programme, called Jackanory, in which somebody would sit down in a big chair and tell a children's story. Our project stemmed from that, thinking about using furniture as a platform whereby we can tell new stories about the environment.

I think there's a lot that we can do around narrative and storytelling to help people visualise what the world needs to look like. We produced a chair, because of its pivotal position in the home; times of celebration, turmoil and happiness. So many different things happen around a chair – it witnesses a lot of family growth. We are trying to paint a different picture of the products and how we use them in order to try extending that connection.

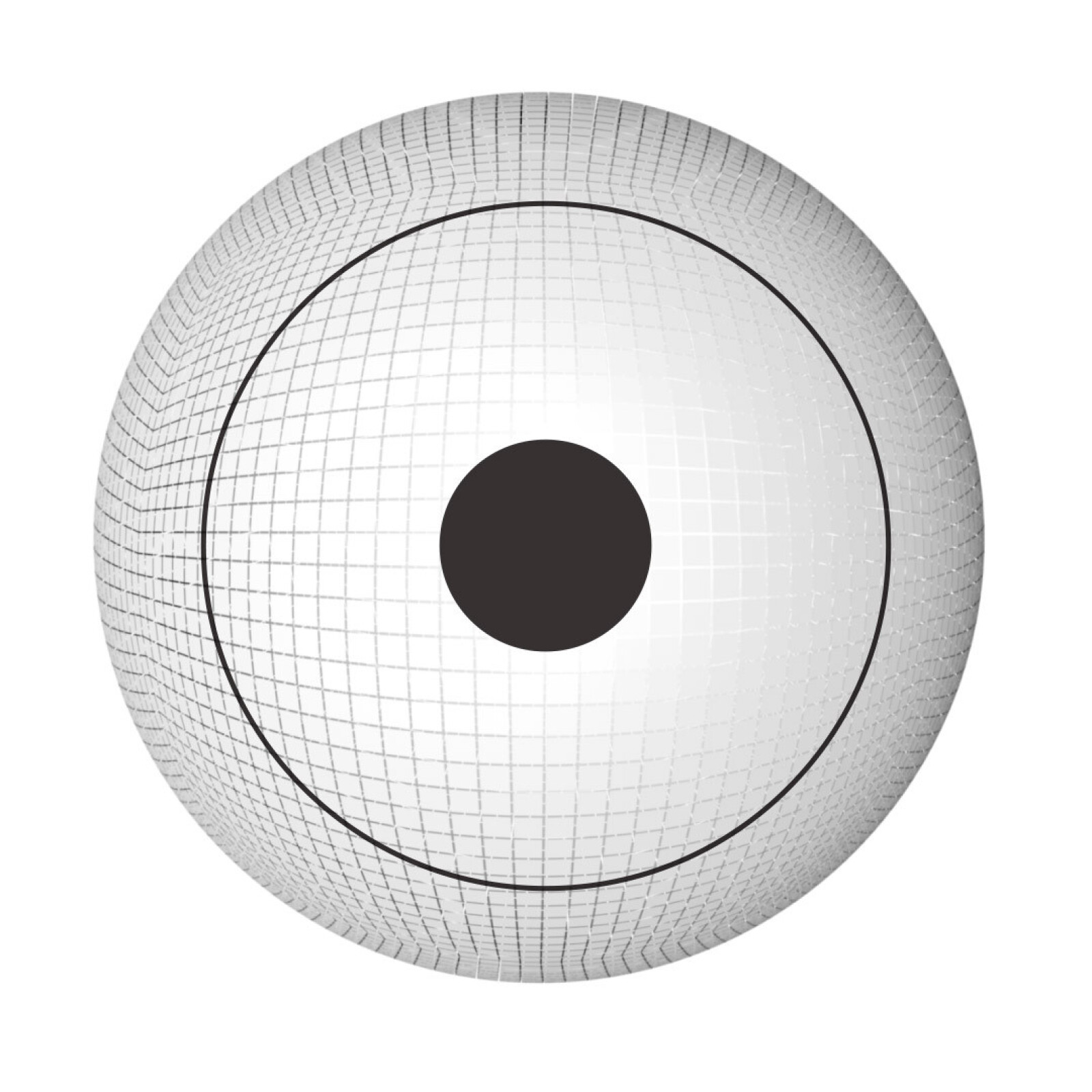

When we started working with the furniture manufacturer, supporting them to improve their sustainability a lot of questions came up around the production process, materials and selling of the products. It is very interesting when a very traditional company, over 100 years old, begins to ask those questions. Our ambition was to understand how we could produce a chair frame through 3D printing using recycled filament from discarded fishing nets collected by Fishy Filaments and use that to close the waste gap in the fishing net industry. The chair frame is then hidden under upholstery, which is where Harris Tweed comes in.

SB

A textile mill produces huge amounts of cloth every year. We aimed to reduce the amount of this cloth going to landfill by using off cuts discarded from the weaving process and odd bits of fabric in the make of the chair.

ACP

How do you see this project evolving in the future?

SB

For the next phase of the project, we are creating a short film and touring the chair so that people can sit on it and tell stories. Additionally, Mark has set up a website for people to send us their stories. We want people to use the chair to voice their concerns about the environment and share their approaches to sustainability.

MB

One of the challenges with this project was to engage different organisations with 3D printers big enough to print the parts that we need to build the chair. It has been quite problematic to engage and realise actual part production through various supply relationships. I think a lot of people imagine that 3D printing is already here, but it's something where a lot of what we're doing is still being understood in terms of material use and ease of use, cost, all sorts of different things. Although in certain areas it has been refined to the point that it can be dependable, in other areas it's still very experimental. There is a whole area that requires a lot more understanding with companies coming on board to make it their areas of expertise.